| |

Cu Ni Co Exaction Reagents

We special to focus on R&D metal extraction reagents, our major products as below:

- P204 (D2EHPA or HDEHP) extractant. This is used for first step to remove impurity for laterite nickel ore.

- DY319 high efficiency nickel cobalt co-extraction extractant for battery recycle, can take out nickel and cobalt together from Lithium battery electrolyte.

- DY272 Nickel cobalt separation extractant, it can take cobalt out from nickel cobalt solution, then leave pure nickel.

- DY988N/DY973N/DY902/DY5640 copper solvent extraction reagent.

- P507 non-ferrous metal extractant for copper, zinc, cobalt-nickel, cadmium, gold-silver, platinum group metals, rare earths and so on.

- DY377 efficient nickel and diamond separation extractant.

- DY366 Scandium extractant.

- DY316 Lithium extractant.

Our R & D team always follow the market needs, not only developed nickel extractants in laterite Nickel ore, Rare earth extractants, Lithium extractants, Vanadium extractants, Beryllium extractants, Rare precious metals (Platinum Iridium Osmium Ruthenium, Palladium and Rhodium) extractants, but also work on Nuclear spent fuel extractants and related extractants in the field of waste battery recycling, always keep on the forefront of industry development.

DZ series Copper leaching reagents:

Specification and Performances:

Item |

DY88 |

DY988N |

DY973N |

DY902 |

Appearance |

Brown oil liquid |

Brown oil liquid |

Brown oil liquid |

Amber oil liquid |

Density (25°C) |

0.91-0.93 |

0.91-0.93 |

0.91-0.93 |

0.95-0.97 |

Flash temperature |

≥62°C (PMCC) |

≥62°C (PMCC) |

≥62°C (PMCC) |

≥62°C (PMCC) |

Solubility of copper-carried organic (25°C) |

≥30 g/L Cu |

≥30 g/L Cu |

≥30 g/L Cu |

≥30 g/L Cu |

Copper saturation capacity 10% (V/V) |

4.8-5.1 g/L Cu |

5.1-5.4 g/L Cu |

5.4-5.7 g/L Cu |

5.6-6.2 g/L Cu |

Extraction kinetics |

≥90% (60s) |

≥95% (30s) |

≥95% (30s) |

≥95% (30s) |

Extraction isothermal point (Organic) |

≥3.8 g/L Cu |

≥4.4 g/L Cu |

≥4.7 g/L Cu |

≥4.7 g/L Cu |

Extraction isothermal point (Aqueous) |

≤2.2 g/L Cu |

≤1.6 g/L Cu |

≤1.3 g/L Cu |

≤1.3 g/L Cu |

Phase Stripping time of extraction |

≤70s |

≤70s |

≤70s |

≤60s |

Stripping kinetics |

≥96% (30s) |

≥95% (30s) |

≥95% (30s) |

≥95% (15s) |

Stripping isothermal point (Organic) |

≤0.6 g/L Cu |

≤1.7 g/L Cu |

≤2.0 g/L Cu |

≤2.3 g/L Cu |

Stripping isothermal point (Aqueous) |

≥33.2 g/L Cu |

≥32.7 g/L Cu |

≥32.7 g/L Cu |

≥32.4 g/L Cu |

Stripping Phase time |

≤80s |

≤80s |

≤80s |

≤60s |

Copper Net Transfer |

3.2 g/L Cu |

2.7 g/L Cu |

2.7 g/L Cu |

2.4 g/L Cu |

Cu/Fe selectivity |

≥2000 |

≥2000 |

≥2300 |

≥2500 |

Compound copper extraction reagent of Ketoxime and Aldoxime can be used alone or mixed with LIX984N, LIX973N, M5640, M5774, CP-150 and N902 in any ratio.

In practice, to produce one metric ton cathode copper, the consumption of Aldoxime will more than 10kg, but Compound Aldoxime & Ketoxime (DY988N) will less than 5kg. The consumption of Compound Aldoxime and Ketoxime reagent will less than single Aldoxime 3-6kg.

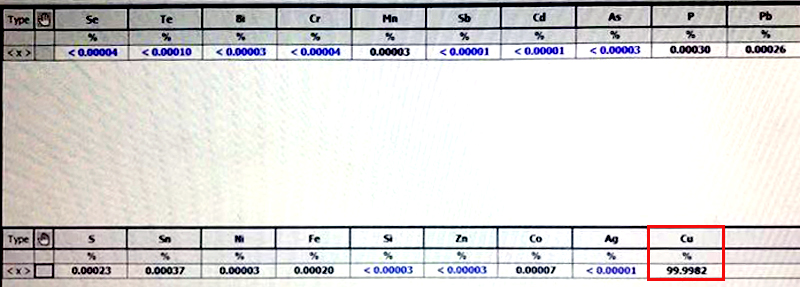

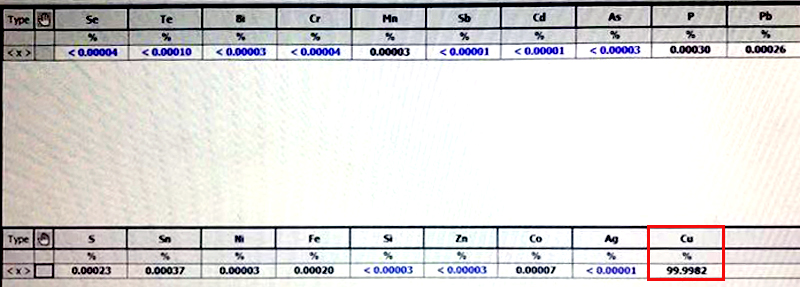

Our engineer is operating a copper extraction plant, the consumption of DZ988N is 2 kg to per ton copper cathode. The purity of copper cathode can reach 99.9982%. The data as below:

Laboratory test process:

Dilute copper extraction reagent: Base the Cu+ content of PLS (Lixivium liquid), add suitable No.260 solvent oil to dilute the organic. Such as the content of copper is 5 g/L, if we use DY988N, the copper net transfer is 2.7 g/L, 0.27 g/100ml, 5/0.27=18.5, so the organic should be dilute to 19%. (Laboratory test usually use 100 ml).

Pour the prepared organic phase to PLS: according to the volume rate of 1:1, and fully mix it over 3 minutes, then record the time to stand the phase till it is separated, you will know the phase separation time. Then pour out the inorganic solution.

Pour 180g/L H2SO4 to the left organic phase in rate of 2:1-4:1 (V:V), and mix it 3 minutes, then record the back extraction time, we will get pure CuSO4. The reverse extracted organic phase can be used again.

If the calculated concentration more than 20%, please change the phase ratio of organic phase to aqueous phase=2:1.

Please click here to view the operation video: https://www.youtube.com/watch?v=-mQ8iWH1LUo

How to make sure our reagent is workable in your plant:

Do above laboratory separately to compare the extraction ability, phase separation time and situation with your using reagent; Take your using organic phase, mix with our organic (V/V, 1:1), then do above laboratory test to check the extraction ability, phase separation situation, and confirm whether it has untoward effect.

If above tests all be normal, it means that both reagents can be mixed to use together.

|

|

DY988N copper solvent extraction reagent |

DY973N copper solvent extraction reagent |

DY88 Ketoxime metal extractant |

DY902 Aldoxime copper extractant |

DY5640 copper leaching solvent |